Your job brings you face to face with major challenges:

💪 Validating the reliability of your parts for applications in harsh environments

✅ Qualifying your parts production (additive or subtractive manufacturing), whether in-house or subcontracted

🚨 Obtain a clear diagnosis following the appearance of damage

Our technicians and engineers provide you with all their responsiveness and expertise to deal with these issues.

Discover ELEMCA's services to meet your needs at every stage of your mechanical parts development.

I WANT TO...

MAKE MY CONCEPTION CHOICES MORE RELIABLE

→ physical/numerical assessment of materials & assemblies

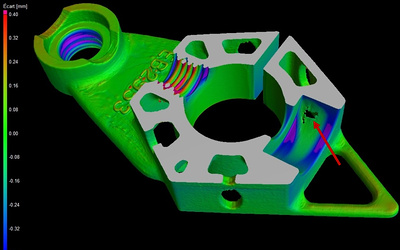

Get a model of any constrained region: mechanical stress, resonant frequencies, ...

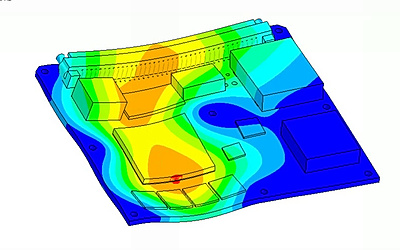

Get the CAO of a part for which I don't have the plans

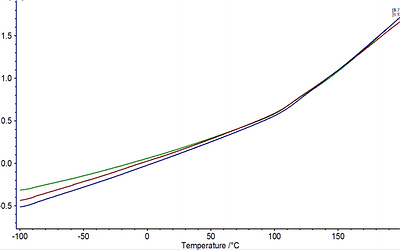

Correlate any process parameter with the material microstructure

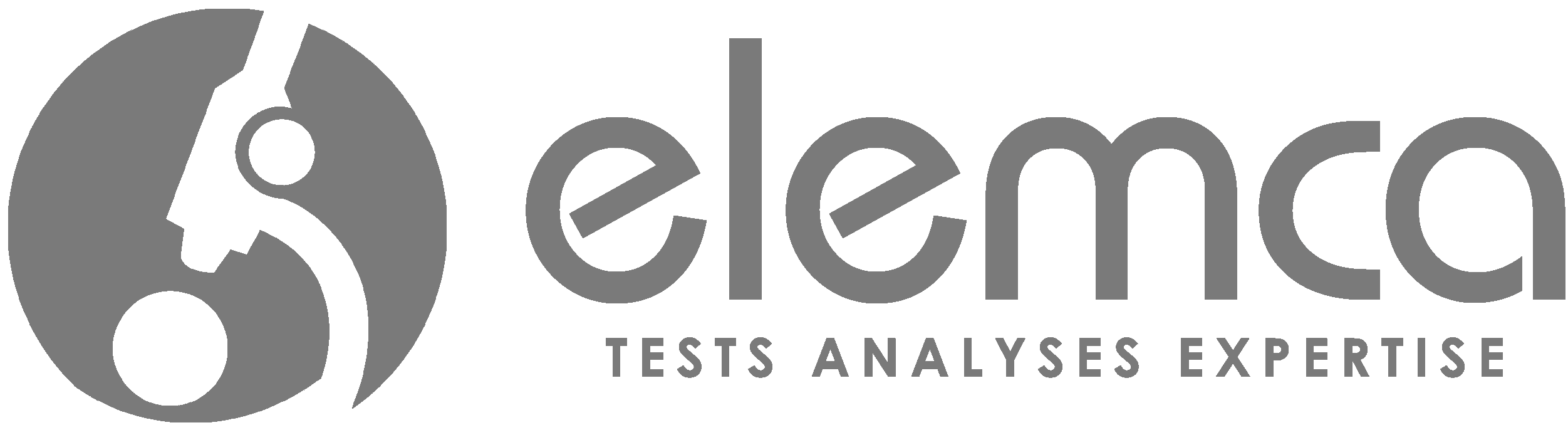

Our studies are based on a mixed numerical and physical approach:

- Numerical simulation of thermal or mechanical behavior

- Material characterization: mechanical, thermal or metallurgical properties

You can put your design choices or the parameters of your special processes to the test, to set them in stone or improve them.

CHECK THE CONFORMITY OF PARTS AND ASSEMBLIES

→ manufacturing quality, qualification

Validate the dimensional conformance and the material health

Characterize the physical properties of a material or control its chemical composition

Assess the behaviour of a part towards harsh environments

Our inspections (X-ray tomography NDT, visual inspection) and tests (thermal cycling, wet heat, thermal vacuum) are carried out in accordance with a broad range of standards (ASTM, IEC, MIL-STD or customer standards).

You ensure the high quality and conformity of your mechanical equipment.

UNDERSTAND THE CAUSES OF DAMAGE

→ identify the root cause, understand degradation or failure mechanisms

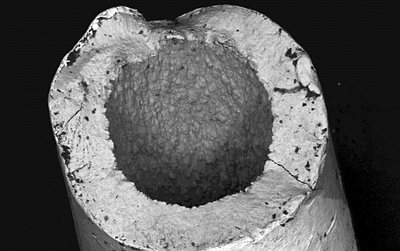

Fractography used to identify the rupture modes

Access the defect to get the accurate characterization, in order to understand its cause

Our Materials & Processes specialists identify and explain the probable root cause and associated failure mechanisms in a detailed expert report.

You know the weak point of your product (design, assembly, integration, use) so you can find an effective corrective solution.