Our equipment dedicated to multiphysical characterization address various needs, on an extended thermal range [-150°C ; +500°C / CTE : + 1500°C ] :

Material benchmark: characterization and comparison of physical properties (hardness, Young modulus, viscoelasticity, glass transition, CTE, outgassing, sorption/desorption…)

Digital simulation

: implementation in a FE model of mechanical / thermal properties

Process optimization : correlate the microstructure

of your parts to its thermal or mechanical performance

Failure analysis: highlight abnormal characteristics (differential dilatation, incomplete reticulation, local hardening)

We perform these multiphysical analyses on many kind of materials: polymers, eg potting (circuit board) or molding resin (components), PCB, tropicalization varnishes and also semiconductors, metal or ceramic parts.

Thermal analyses

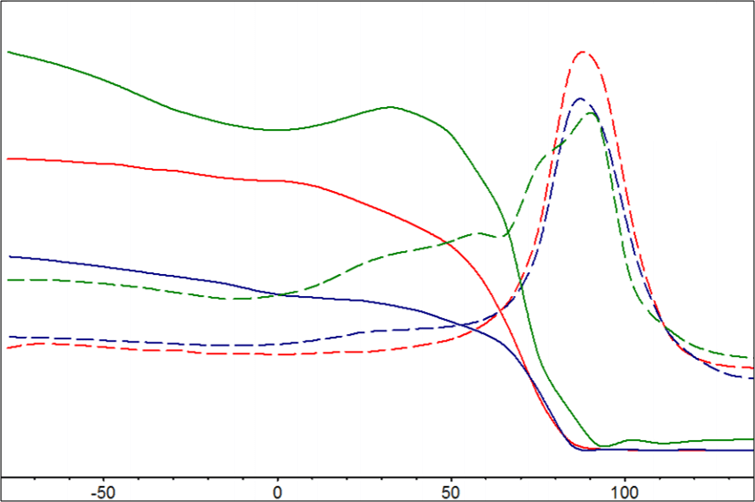

CTE / Coefficient of Thermal Expansion (TMA or dilatometry)

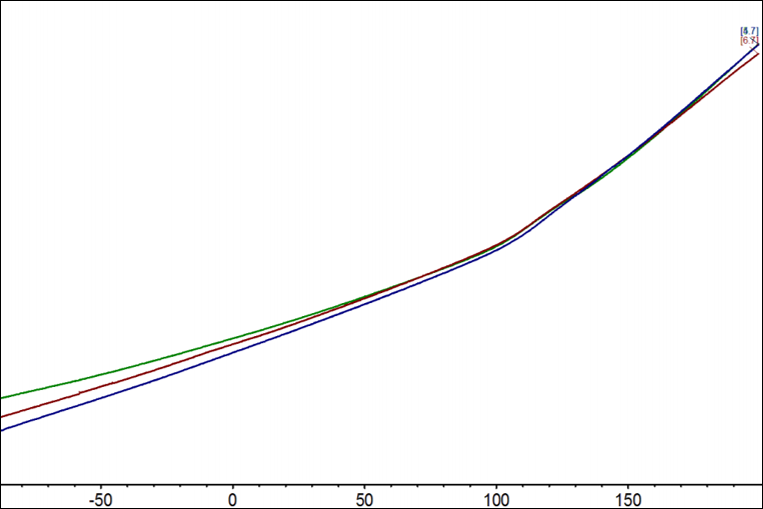

Viscoelasticity / complex Young modulus E* (DMA)

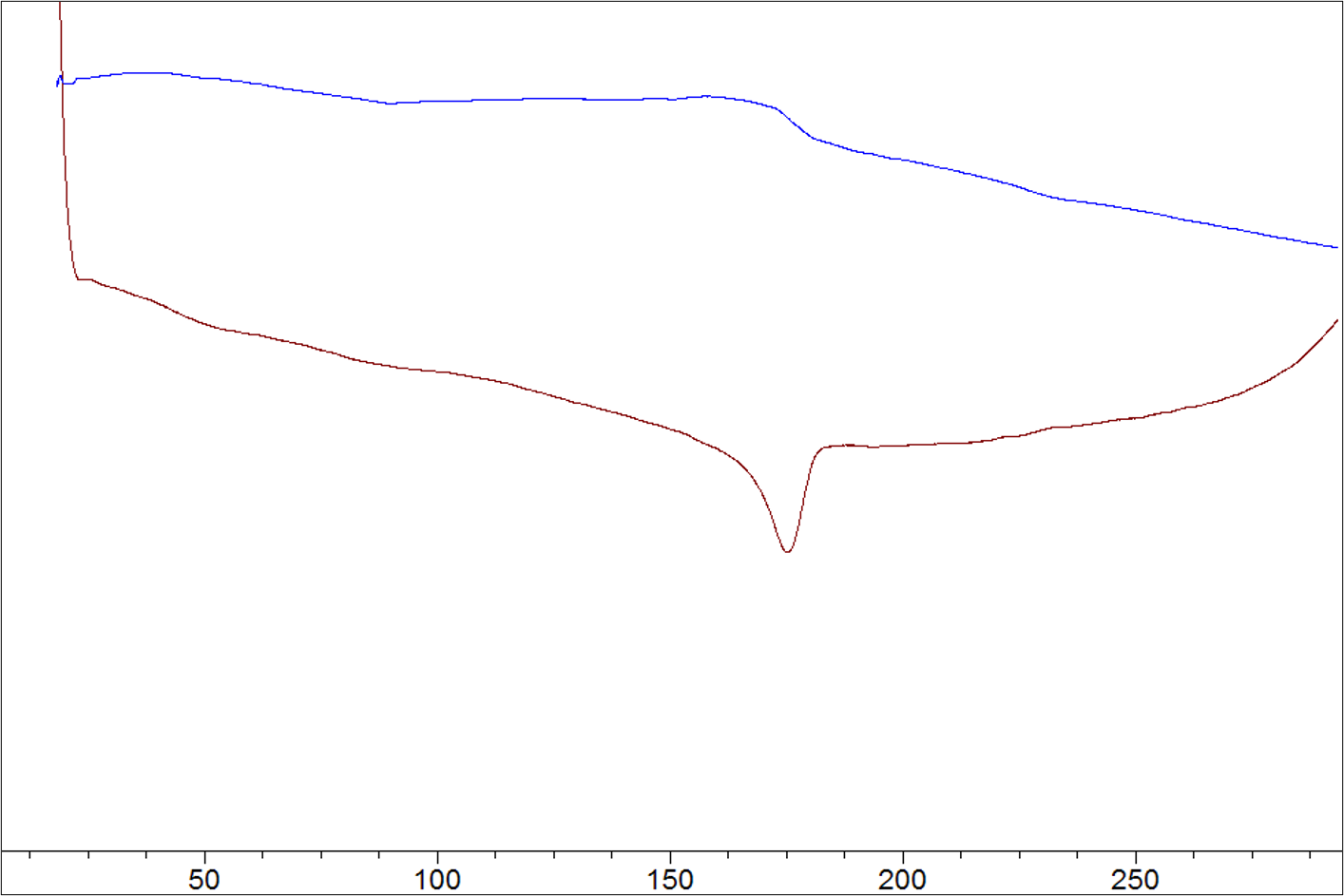

Tg / Temperature of Glass transition (DSC)

Kinetic of reticulation (DSC)

Contamination

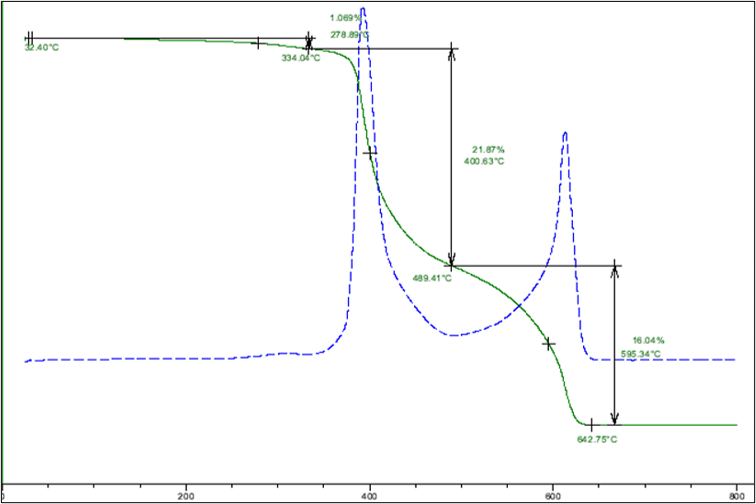

Outgassing of volatile compound at ambient pressure (ATG)

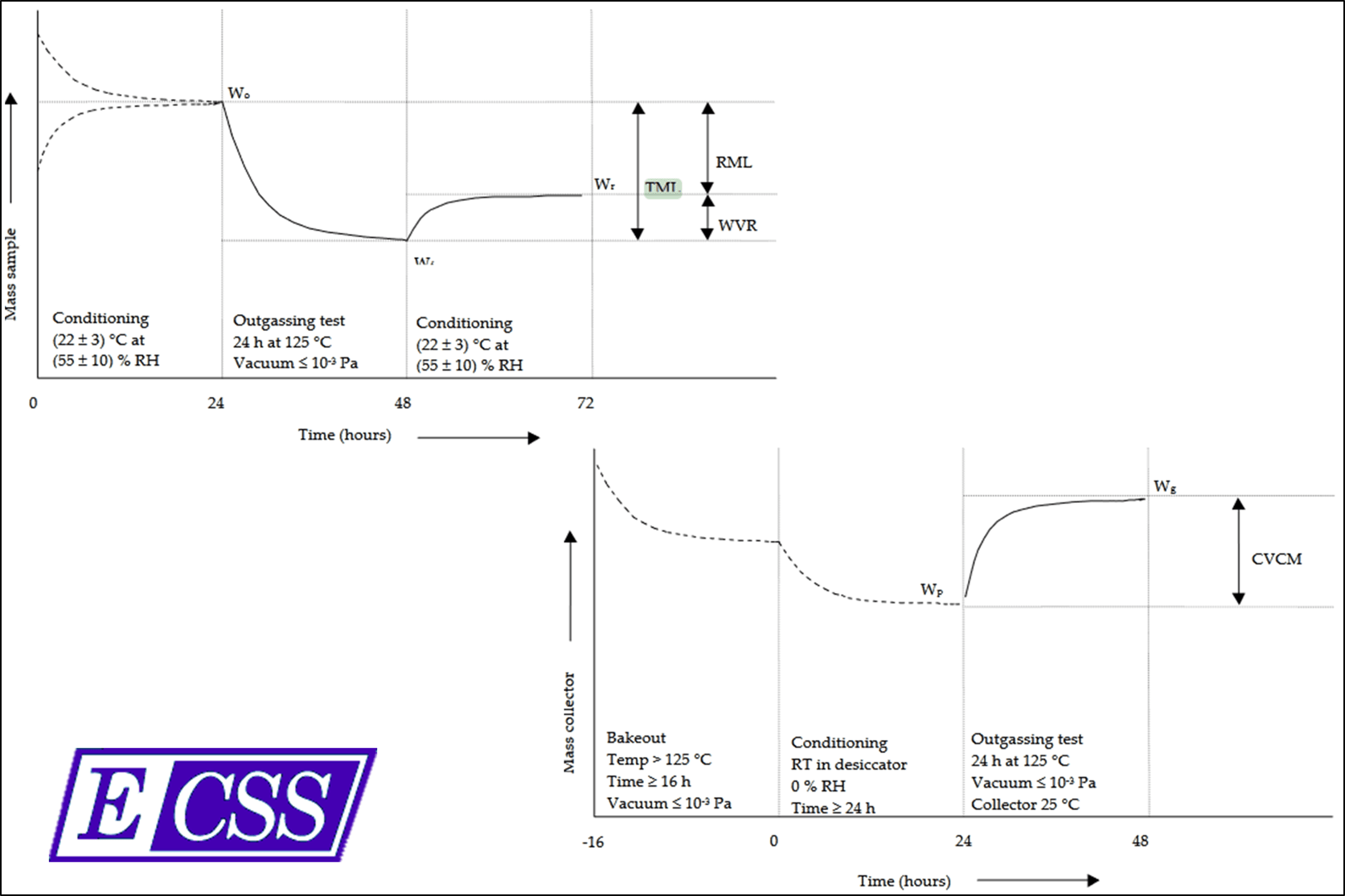

Outgassing under thermal vacuum; ECSS-Q-70-02 protocol and criteria (TML, RML, WVR, CVCM)

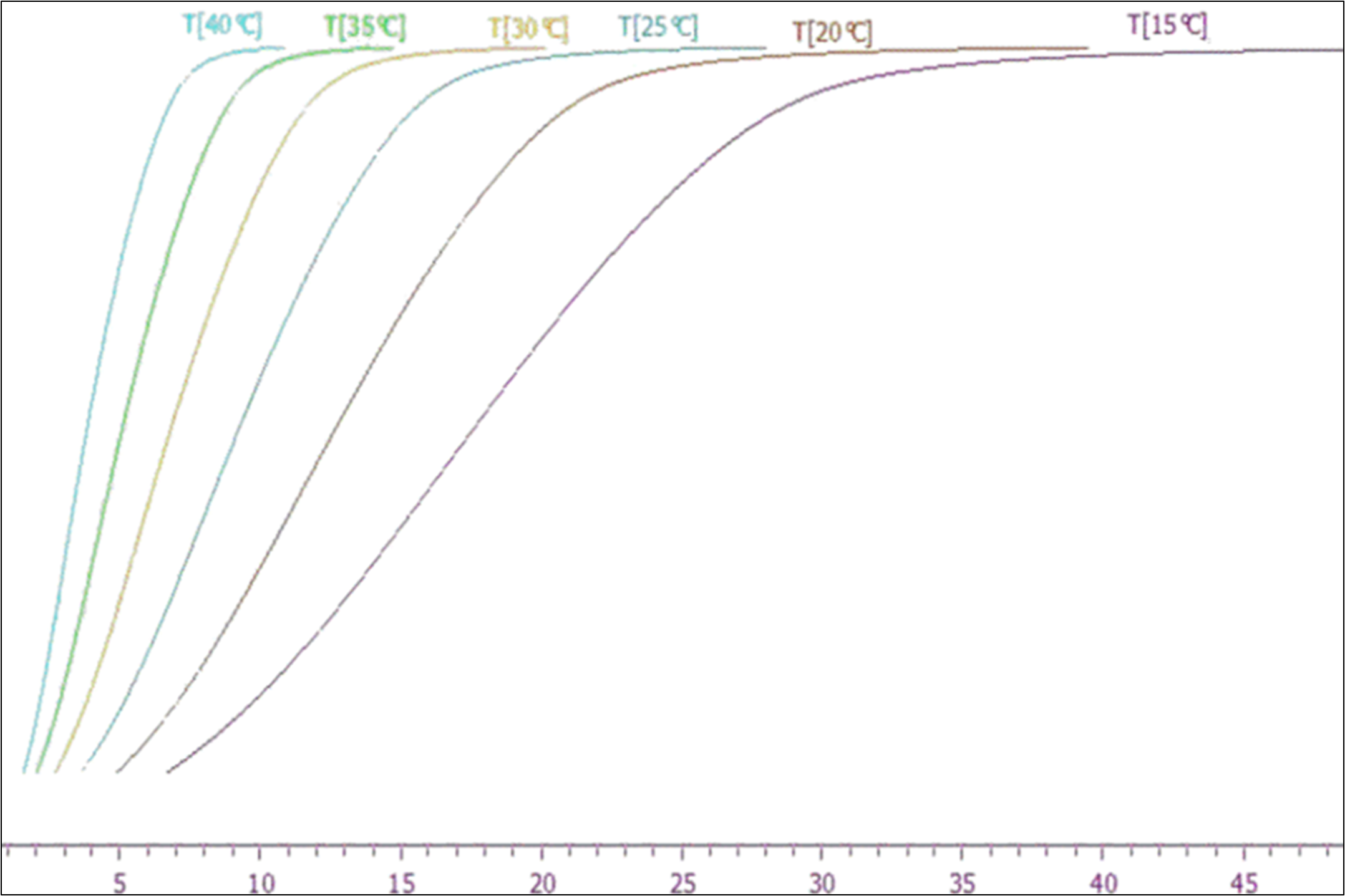

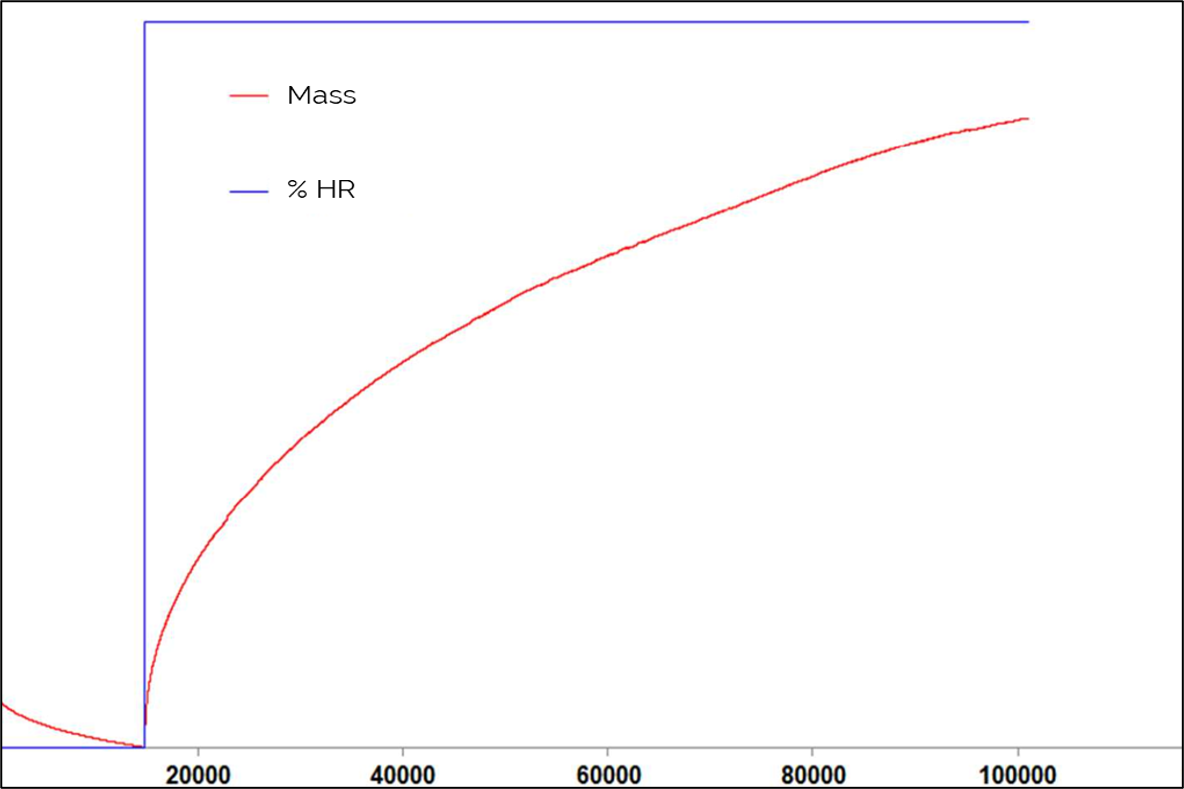

Measurement of sorption / desorption (DVS)

Mechanical characterization of locale properties & thin film

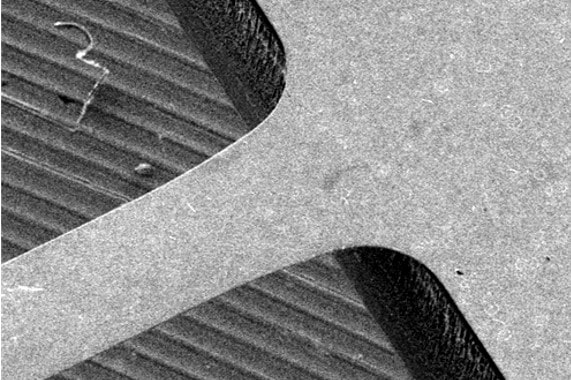

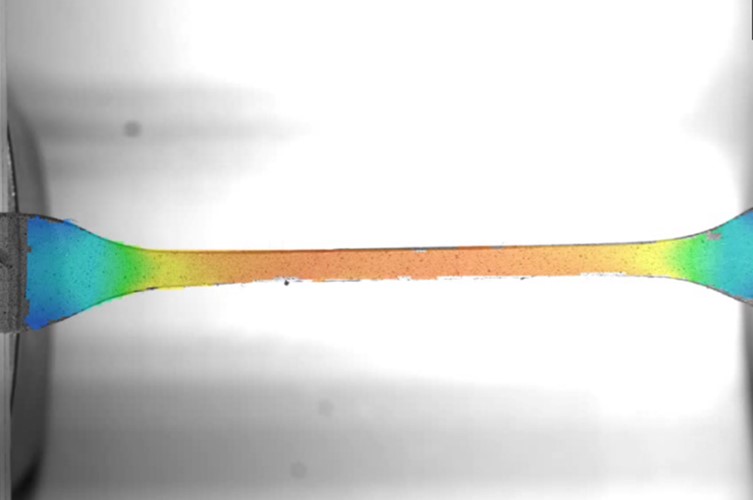

Microtensile test on self-standing thin layers (~1µm thick) or submillimetric wires

Nanoindentation: Berkovich hardness + Young modulus

Static mechanical tests

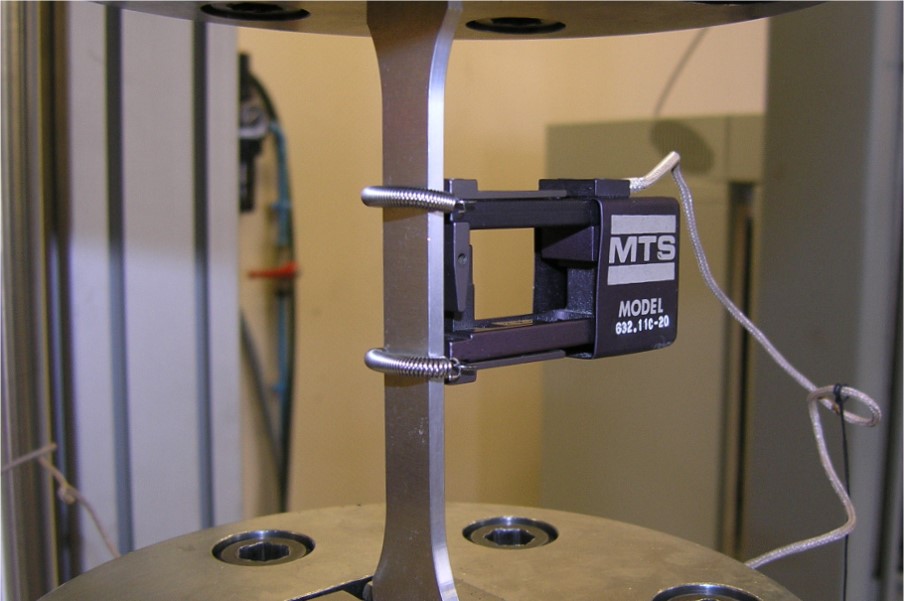

Universal testing machine, at steady temperature [-80°C ; + 250°C] :

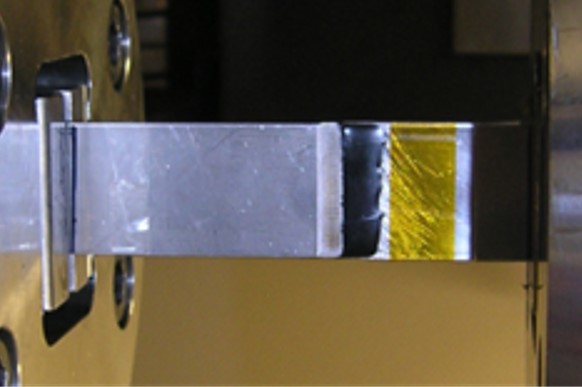

Uniaxial tensile test

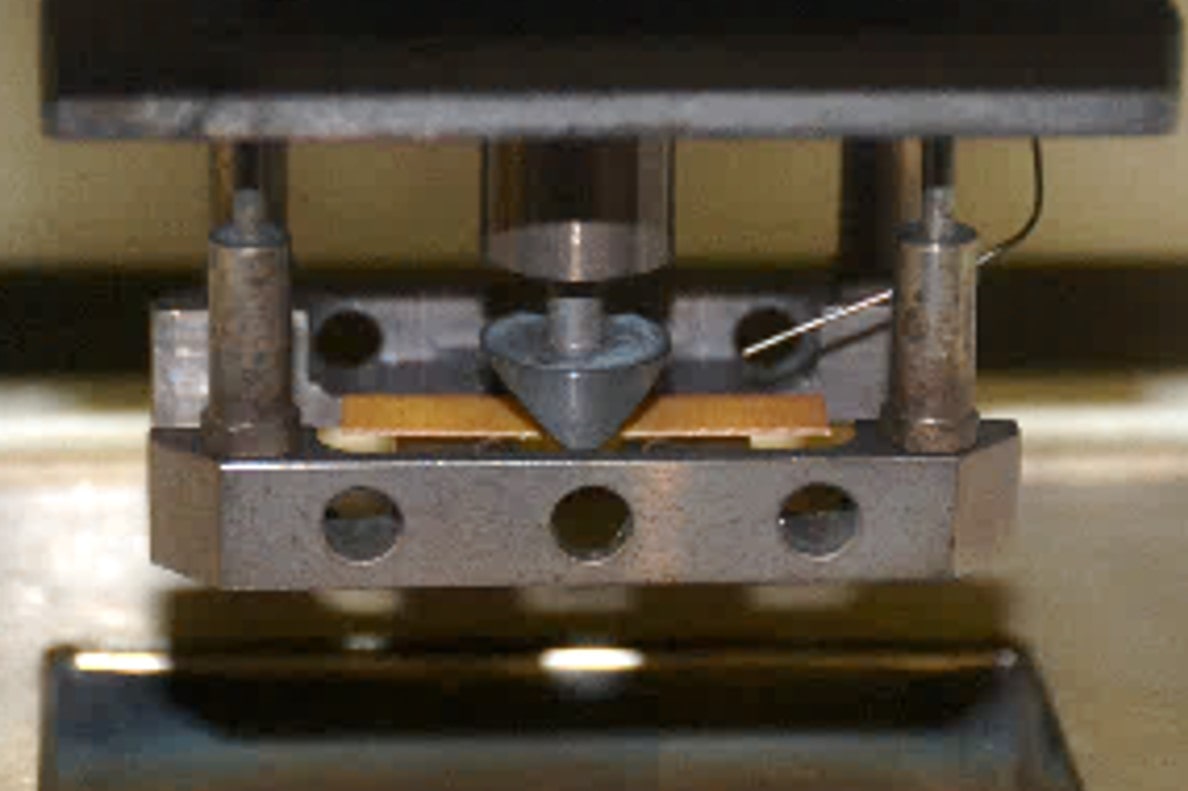

3 points bending

Shear test

Option (flexible or complex samples): digital image stereo-correlation

Do you want a detailed presentation of our Lab services or consult us on a specific need ?