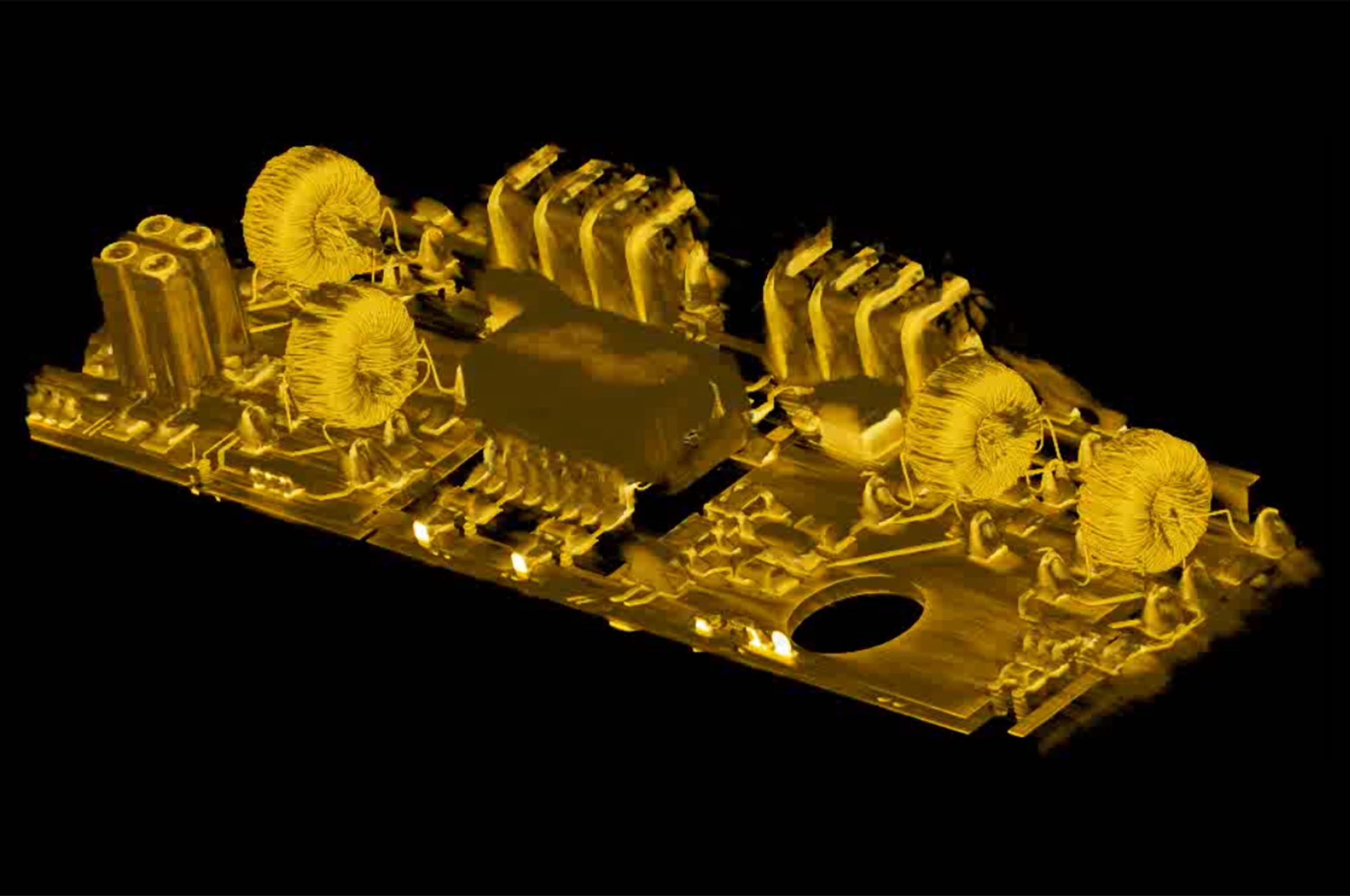

We use our X-ray radiography and IR thermal imaging equipment to answer your various needs :

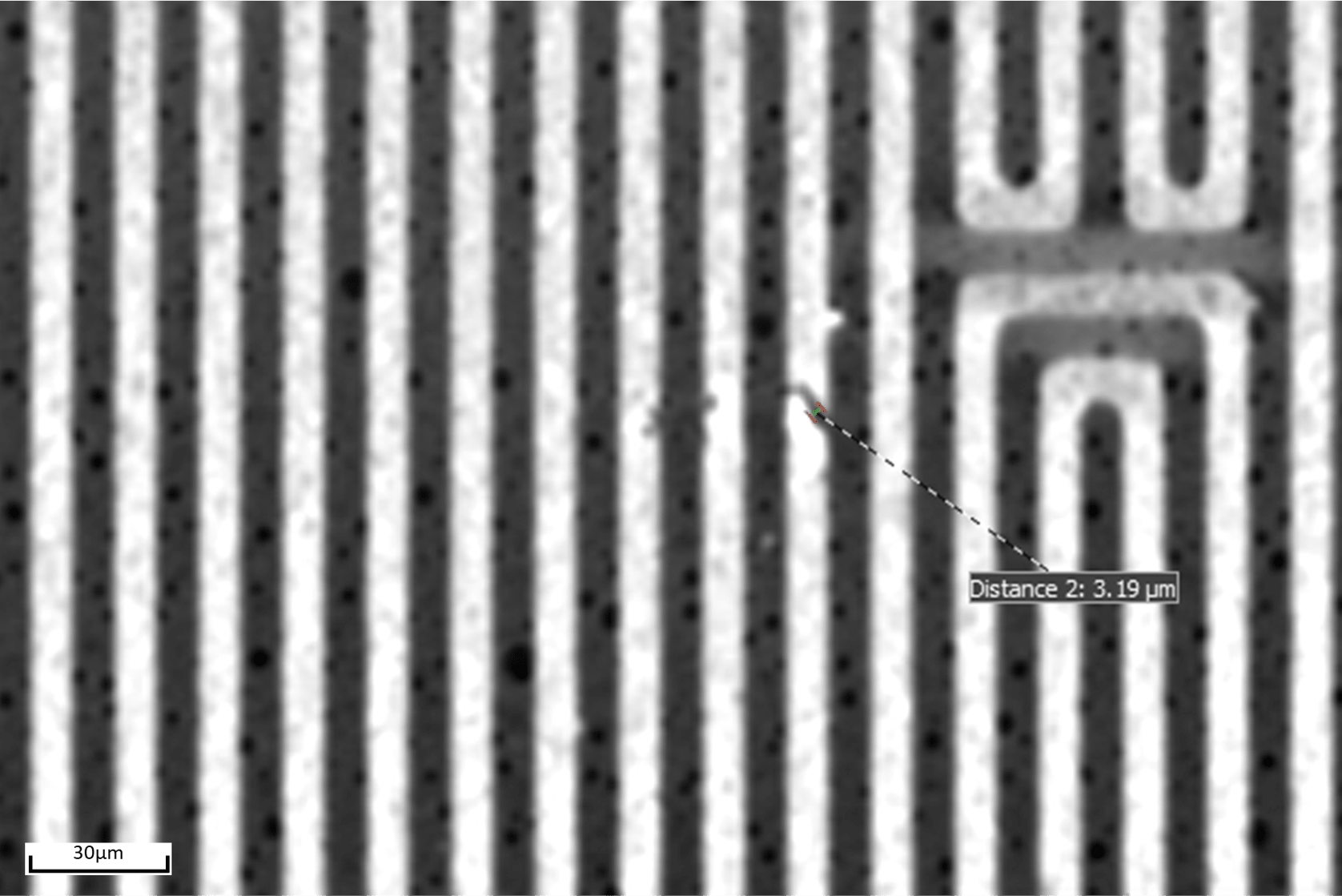

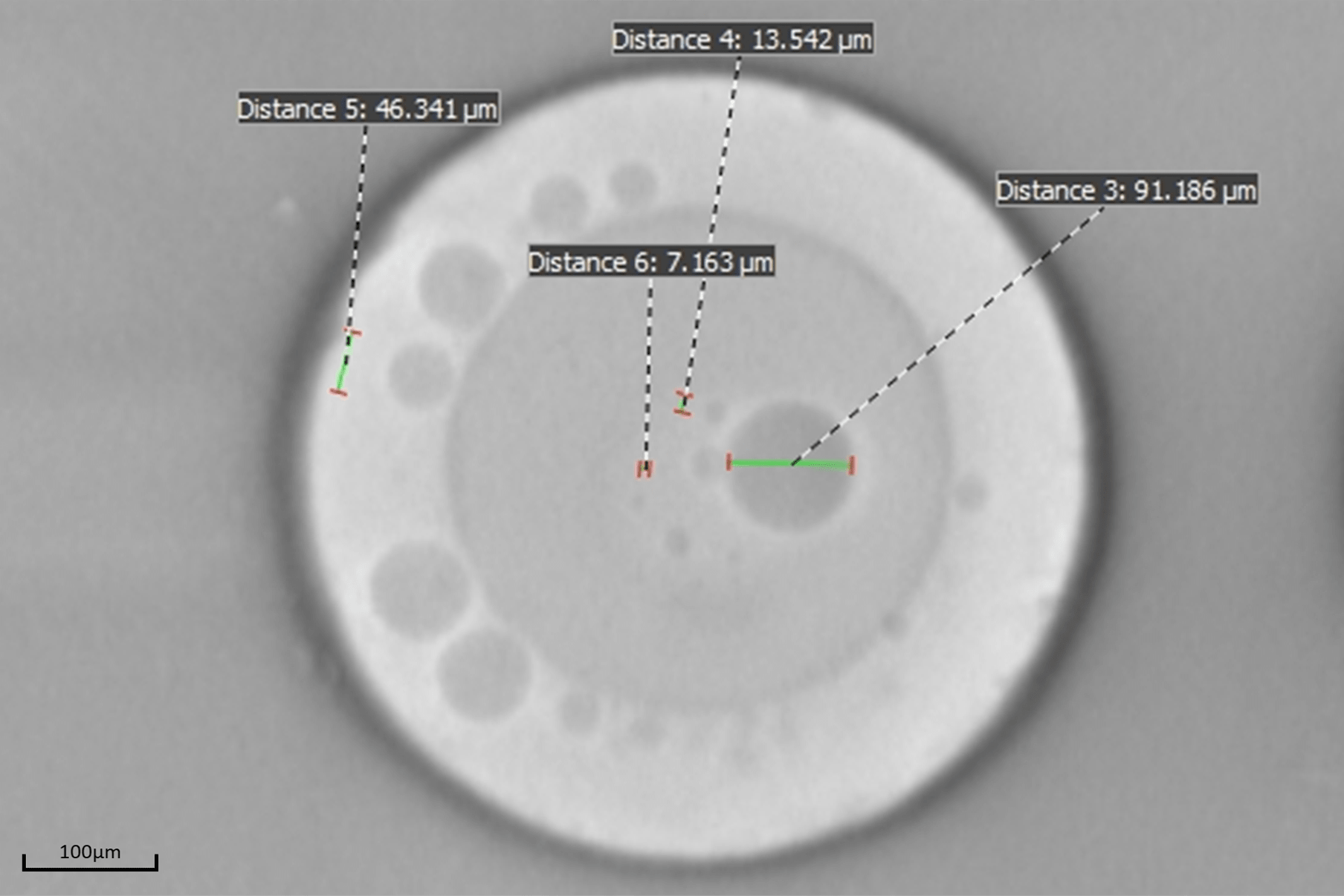

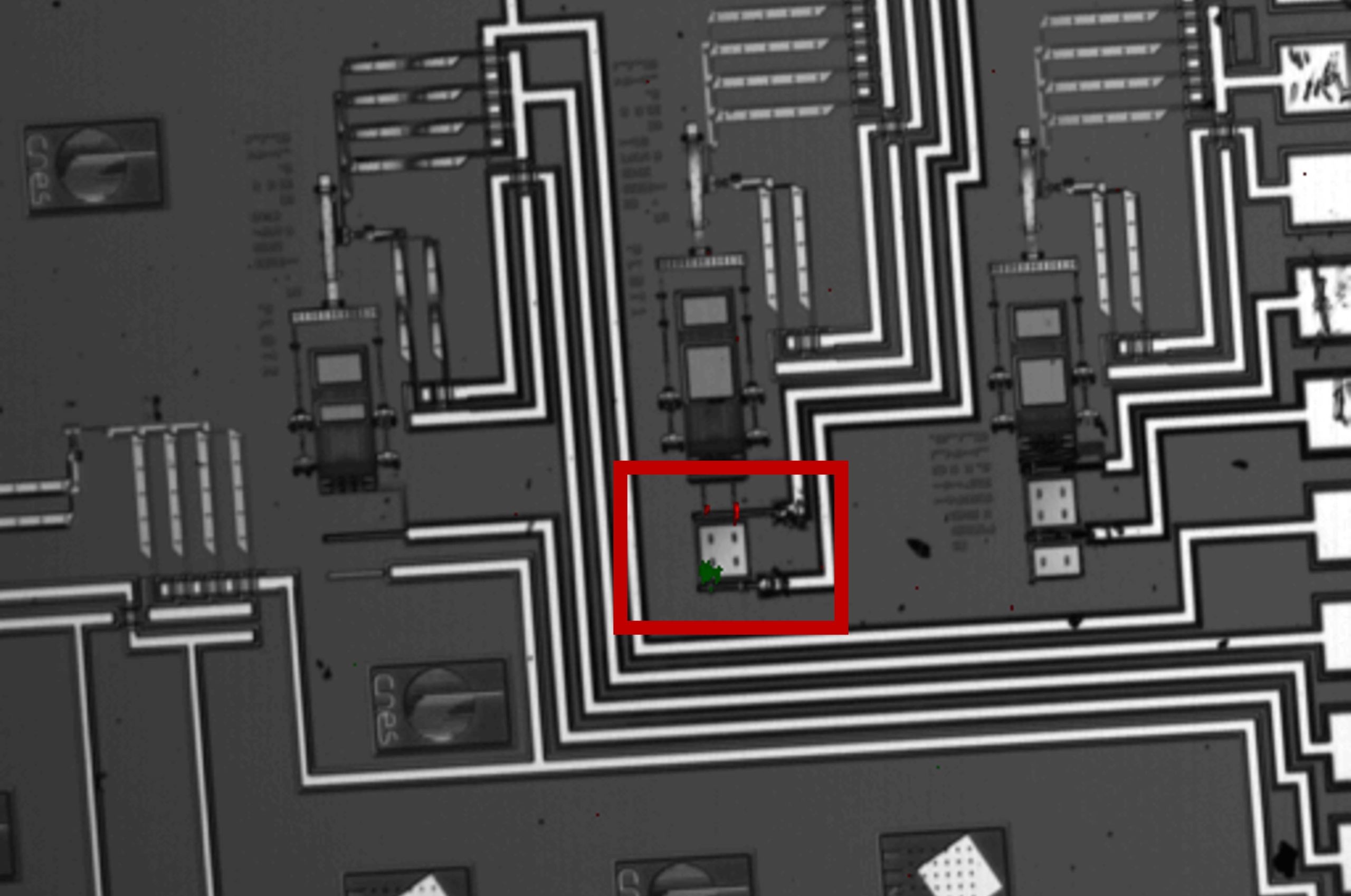

Failure analysis on electronic devices: detection of physical (X-ray CT) or thermal anomalies (LIT). After a preliminary electrical test (failure mode), the defect thus spotted will then be inspected by optical or electronical (SEM) microscopy, generally after microsection or package opening

Reverse engineering: localization of the key internal parts, inside a SiP or a molded device, before technological analysis

IPC-A-610 compliance

: through-hole filling, 2D void ratio

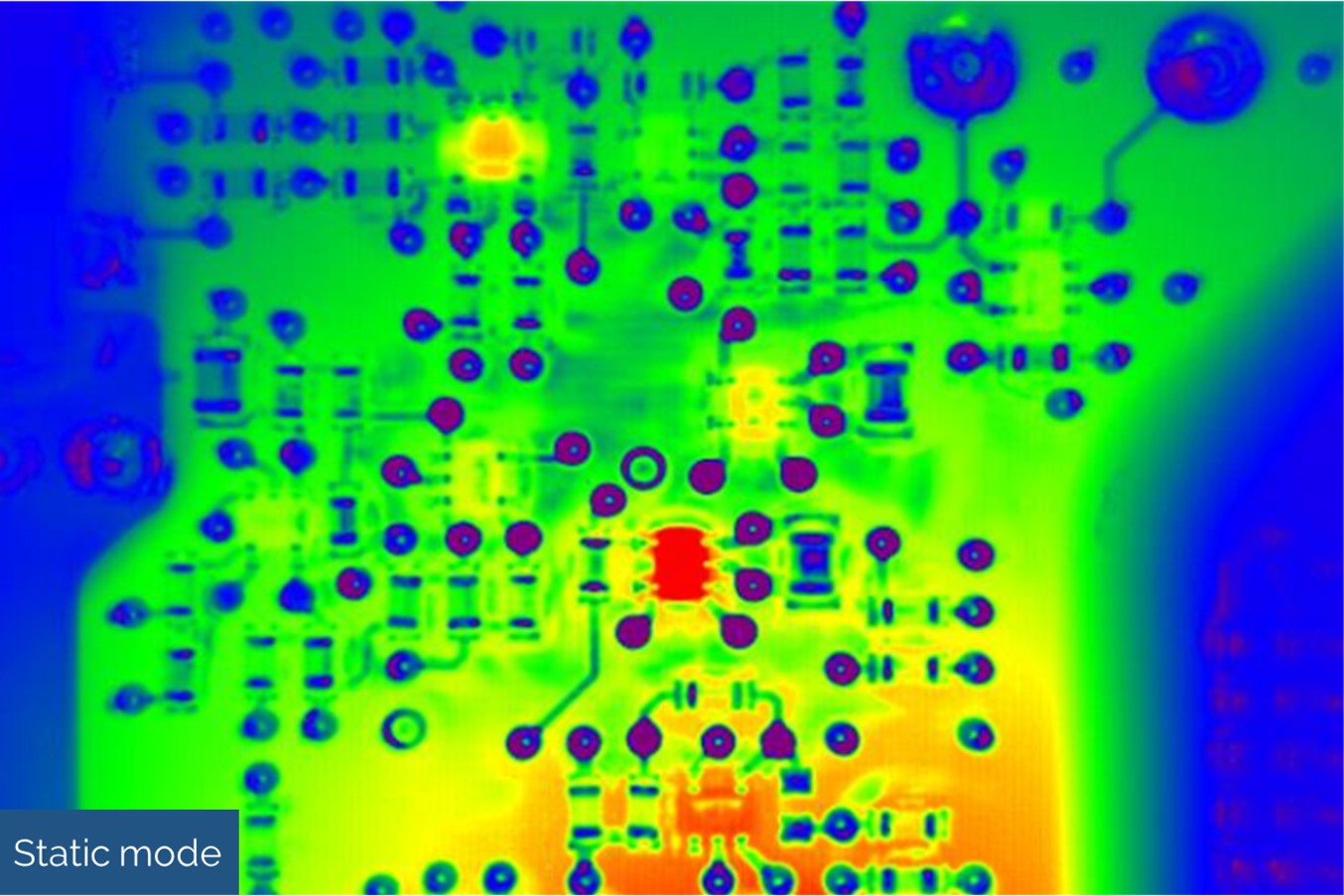

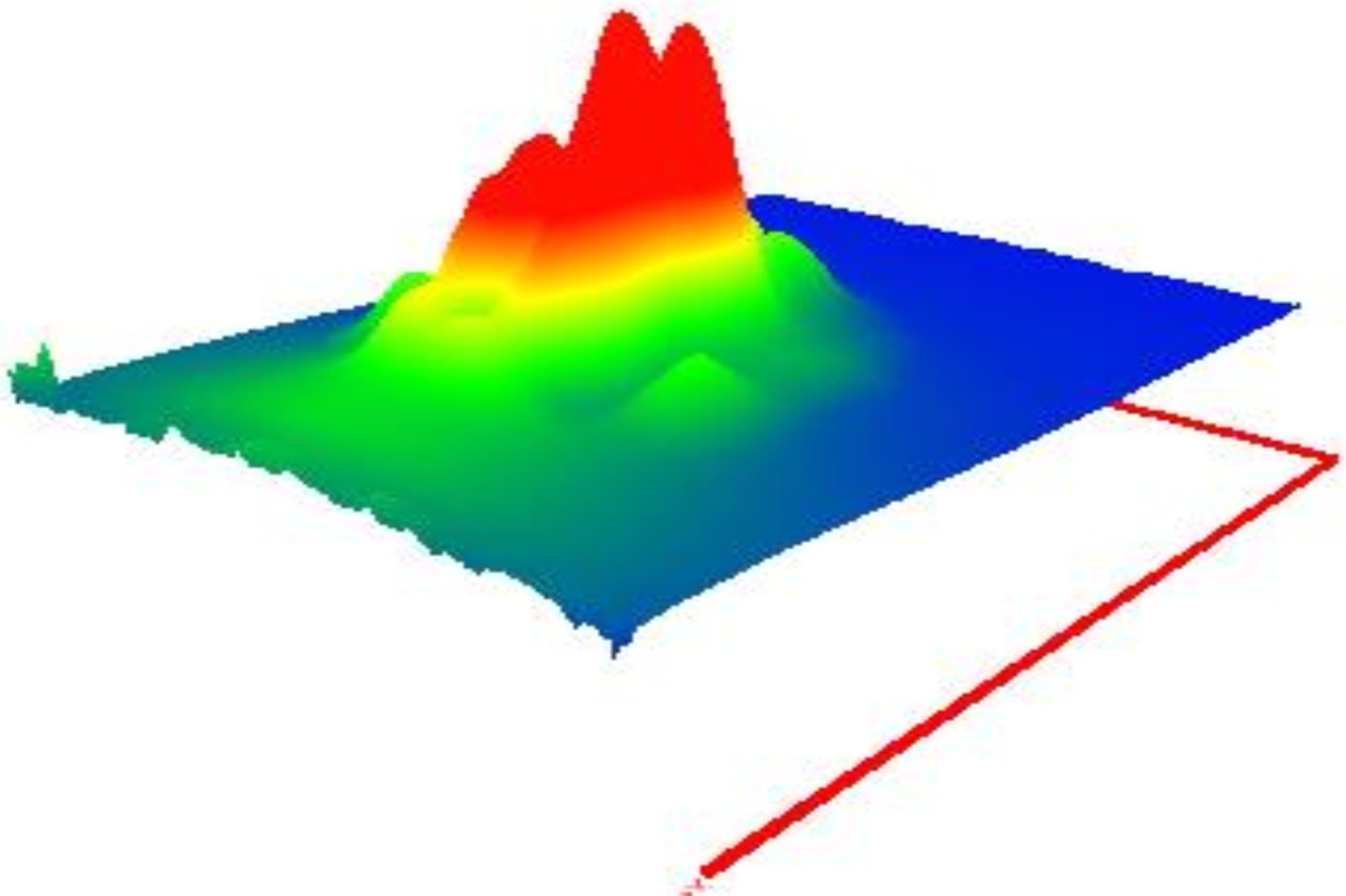

Thermal cartography (steady mode), in comparison with a digital simulation

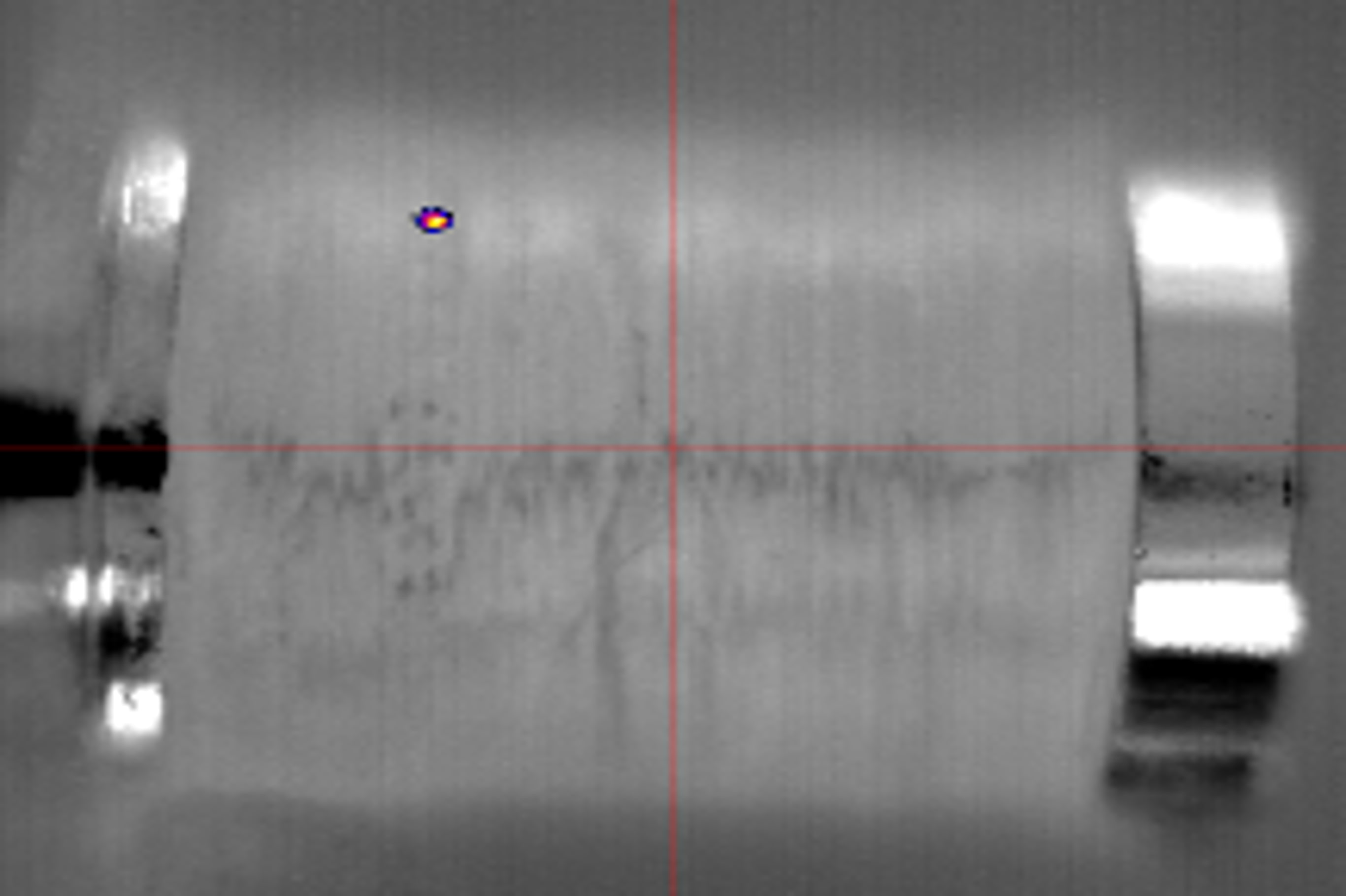

Measurements of thermal resistance (Rth), after package opening

We lead these non-destructive analyses on electronic components (MEMS, sensors, passive, discrete, electromechanics), printed circuit boards (bare, assembled, molded) and connectors.

Lock-in IR Thermography / LIT

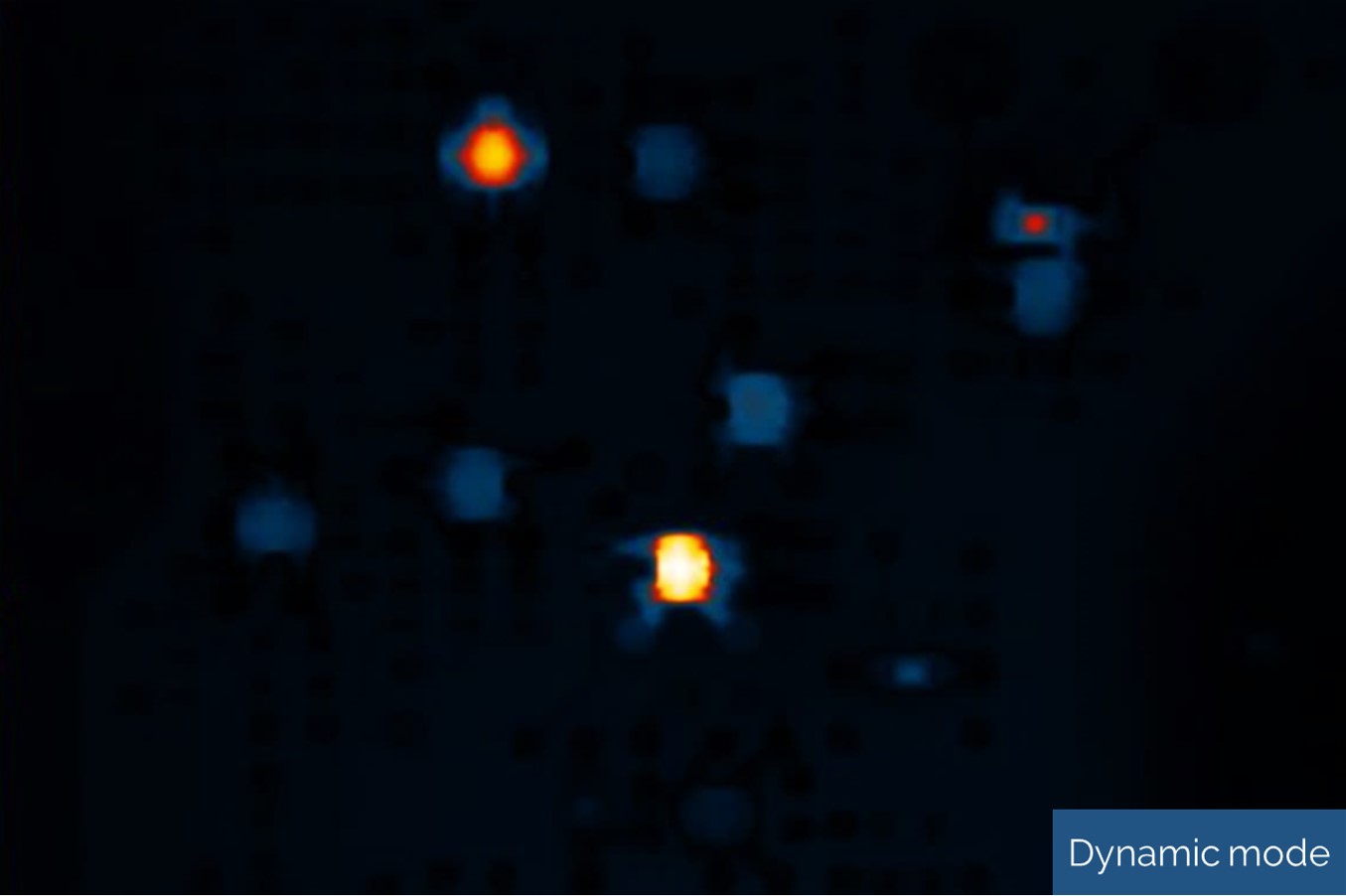

IR thermal mapping : static mode (PCBA overall heatness) ; dynamic "LIT" mode (tiny hot spots localization)

Detection of leakage current (LIT)

Accurate temperature measurement (LIT)

Do you want a detailed presentation of our Lab services or consult us on a specific need ?