Verifying the authenticity of components or their homogeneity within a batch is a major challenge today. Particularly when you're sourcing them from new intermediaries, or from older batches (integrity after long-term storage).

The testing protocol applied by ELEMCA complies with current standards:

- IDEA-STD-1010: Acceptability criteria. Acceptability of Electronic Components Distributed in the Open Market

- AS6171A and or ISO 2859-1: inspection methods and sampling rules (number of components to be analyzed according to the size of the batch supplied).

The aim of these checks is to assess the conformity of the components under test with regard to their expected characteristics: external visual appearance of the package and terminations, dimensions and integrity of the chip, bondings and leadframe, electrical functions, pin wettability.

Our verifications are based on an extensive ELEMCA database of findings on both genuine components and proven counterfeits.

The techniques we use are adapted to the suspected level of counterfeit refinement, as well as to the criticality and technology of the component.

Non destructive testing

Destructive analyses

External visual inspection

Marking test

X-ray imaging

Acoustic microscopy

X-ray fluorescence

Electrical test

Solderability

These tests are carried out on all families of electronic components (active, discrete, passive), new or after long-term storage.

Standard tests: counterfeiting detection

Aim: point-out actual counterfeited parts

External visual inspection, marking

MIL-STD-883 Test Method 2009, SCC 24800

Marking test

ESCC 24800

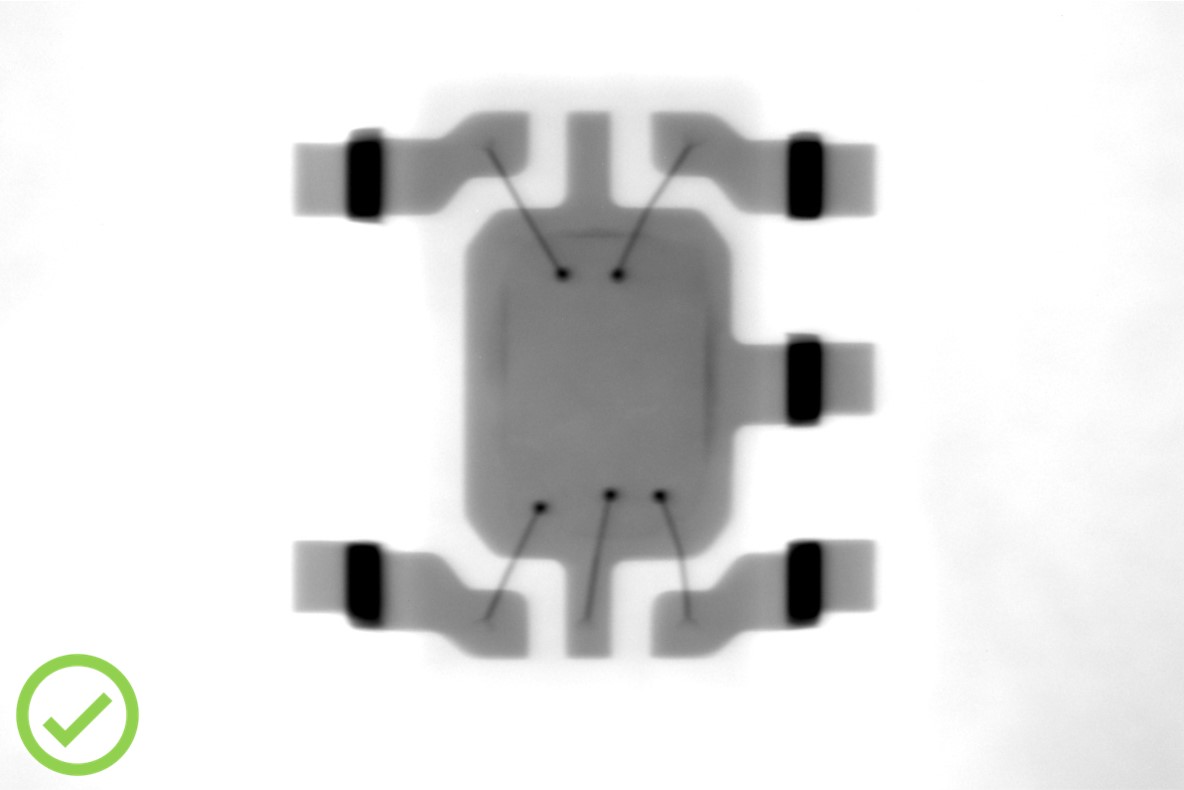

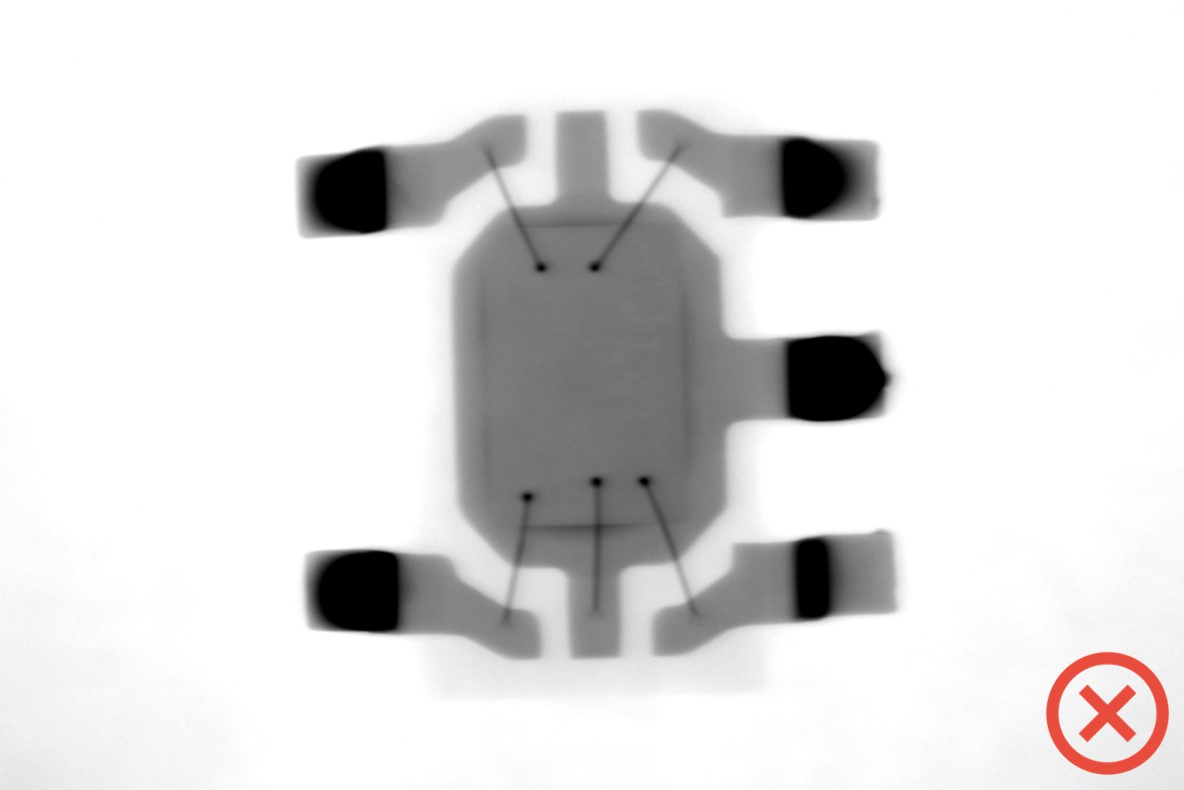

X-ray imaging

MIL-STD-883 Test Method 2012

Internal visual inspection after package opening

MIL-STD-883 Test Method 2010

External visual appearance: integrity of the package (marking: typography, punch) and terminations (absence of traces of flux or residual solder indicating a component unsoldered after first use)

Solvent or scalpel test: no sign of blacktopping

Scalpel or solvent (acetone) test: evidence of package remarking

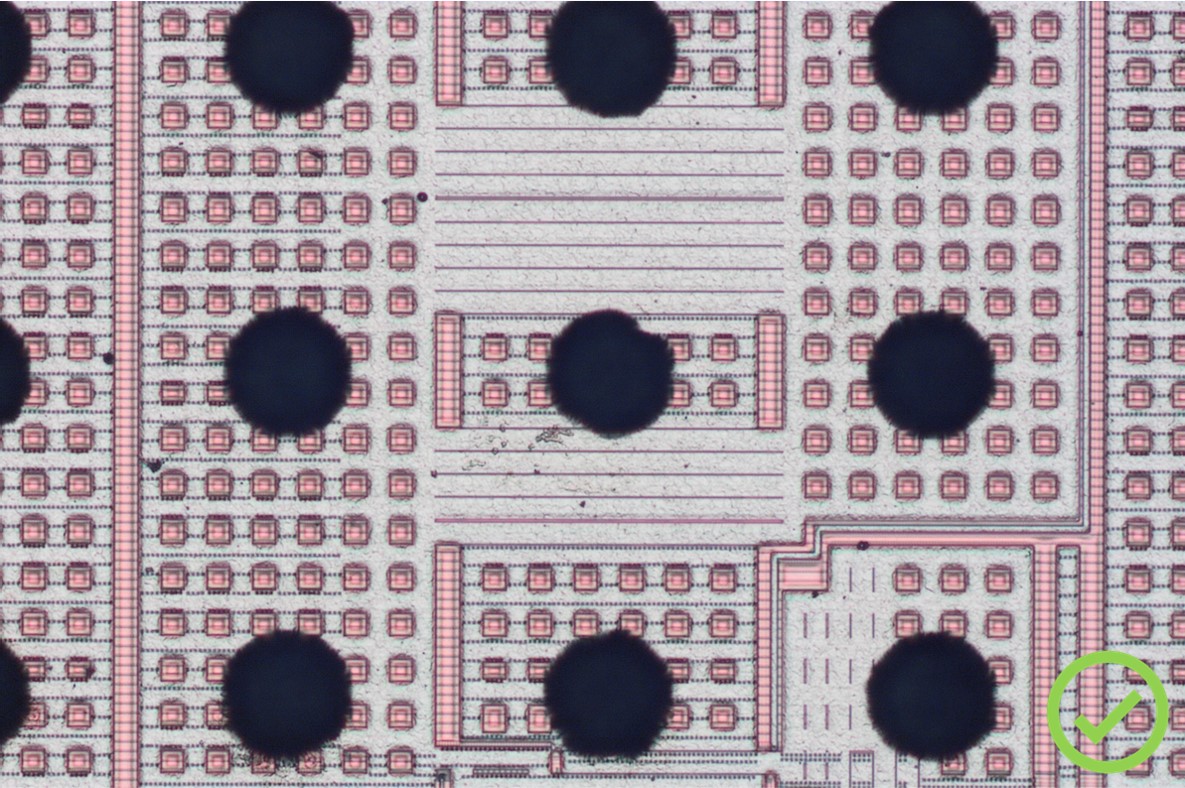

Non-destructive inspection of the elements inside the case: presence of the chip; chip and leadframe dimensions, position and geometry; integrity of interconnections (bondings): diameter, absence of breakage

Correspondence between the serial number of the chip and the one of the package. Comparison with our Components database; absence of anomaly on the chip (connection of bonds, alterations, tool marks, scratches, cracks, stains, traces of corrosion or contamination); passivation layer integrity

Advanced tests : Batch quality and homogeneity

Aim: evaluate the scattering amongst a batch (same date-code) or aging due to long-term storage

Acoustic microscopy (CSAM)

IPC/JEDEC J-STD-035, MIL-883 Method 2030.2

Solderability

IEC-68-2-20 Test Ta Method 1

X-ray fluorescence

Electrical measurements

At room or high temperature

Absence of any critical defect: delamination or crack in the die attach or at the interface between the case and the leadframe / paddle

Observation of the solder wetting region; quality of wettability (good adhesion between the terminations and the solder)

Verification of the termination composition: absence of Lead for RoHS components

Confirmation of electrical characteristics: parametric I(V) or functional tests

Do you want a detailed presentation of our Lab services or consult us about a specific need ?