We control the quality of your electronic boards dedicated to demanding markets. The acceptance criteria and applicable standards depend on the aimed application:

Printed Circuit Board Assemblies (solder joints)

- ECSS-Q-ST-70-61C: legacy space (sciences, observation, defense, telecom)

- IPC-A-610: new space (IoT constellations, smallsats), aeronautics, automotive, railway, naval, energy

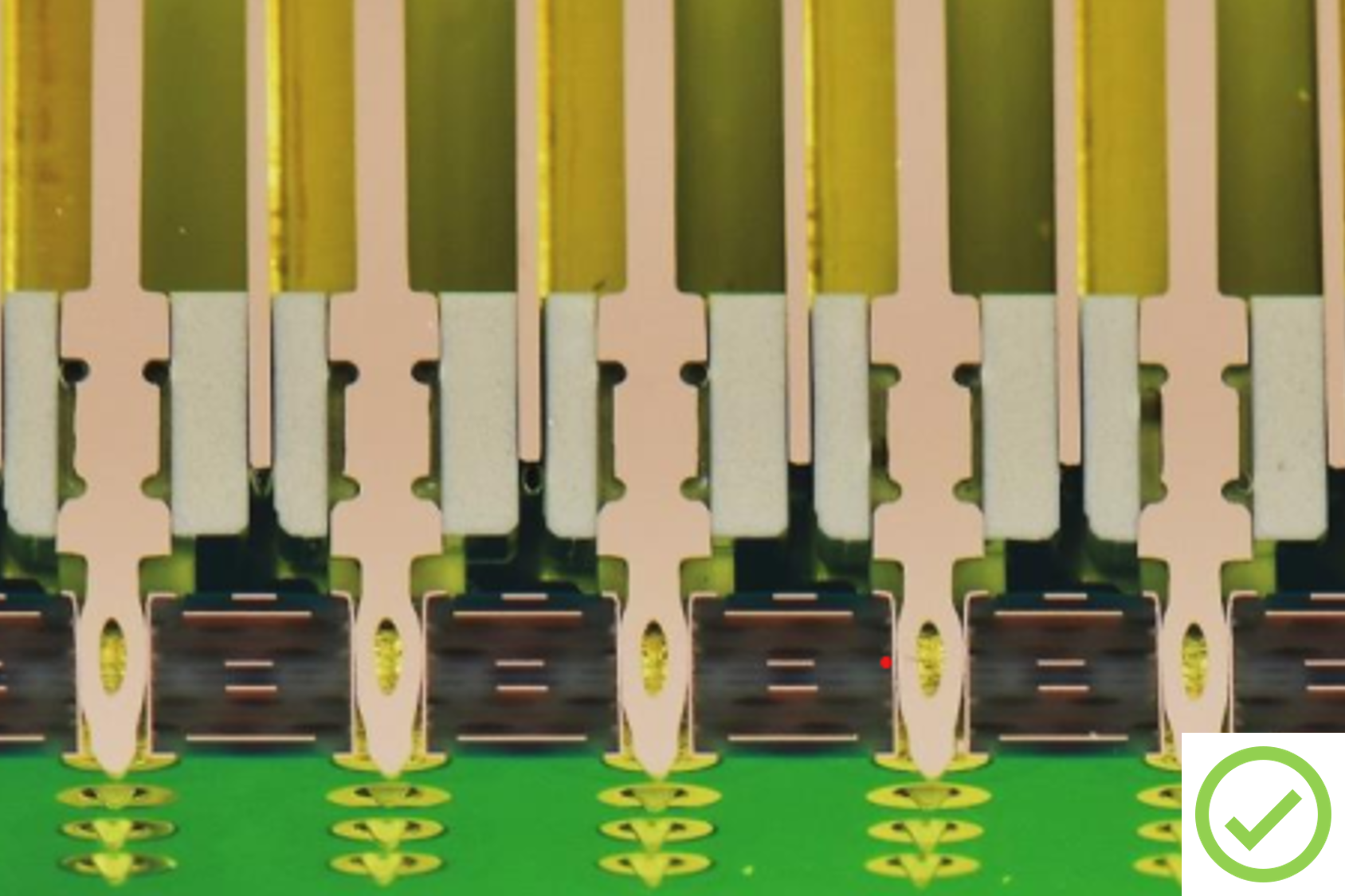

Printed Circuit Board Assemblies (pressfit)

- IPC 9797

Bare Printed Circuit Boards

- IPC-A-600 (flex & rigid PCB)

- IPC-6012 (rigid PCB)

- IPC 4552 (specific to ENIG finishes)

Wires / crimping

- ECSS-Q-ST-70-26C : space application

- IPC-A-620

ELEMCA is recognized as Category A laboratory and recommended by ESA for these ECSS-compliance verification. ESA recommended microsectioning facilities list (PDF)

Our inspections and controls rely on every constitutive elements of your electronic assemblies: solder joints, printed circuit, components, connectors, coating.

The protocol of IPC-A-610 standard is based on 2 inspection steps, as ECSS-Q-ST-70-08C/38C has a destructive, extra step (optical microscopy on microsection):

Our team is certified (IPC, ECSS) and our laboratory has the appropriate analysis and control techniques:

Non-Destructive Testing

Physical Analyses

External visual inspection

X-ray radiography

Ionic contamination

In addition to the final Compliance report and if you need fast, direct follow-up, you may access to your results all along the campaign. This “Quick access to results” feature is free.

External visual inspection

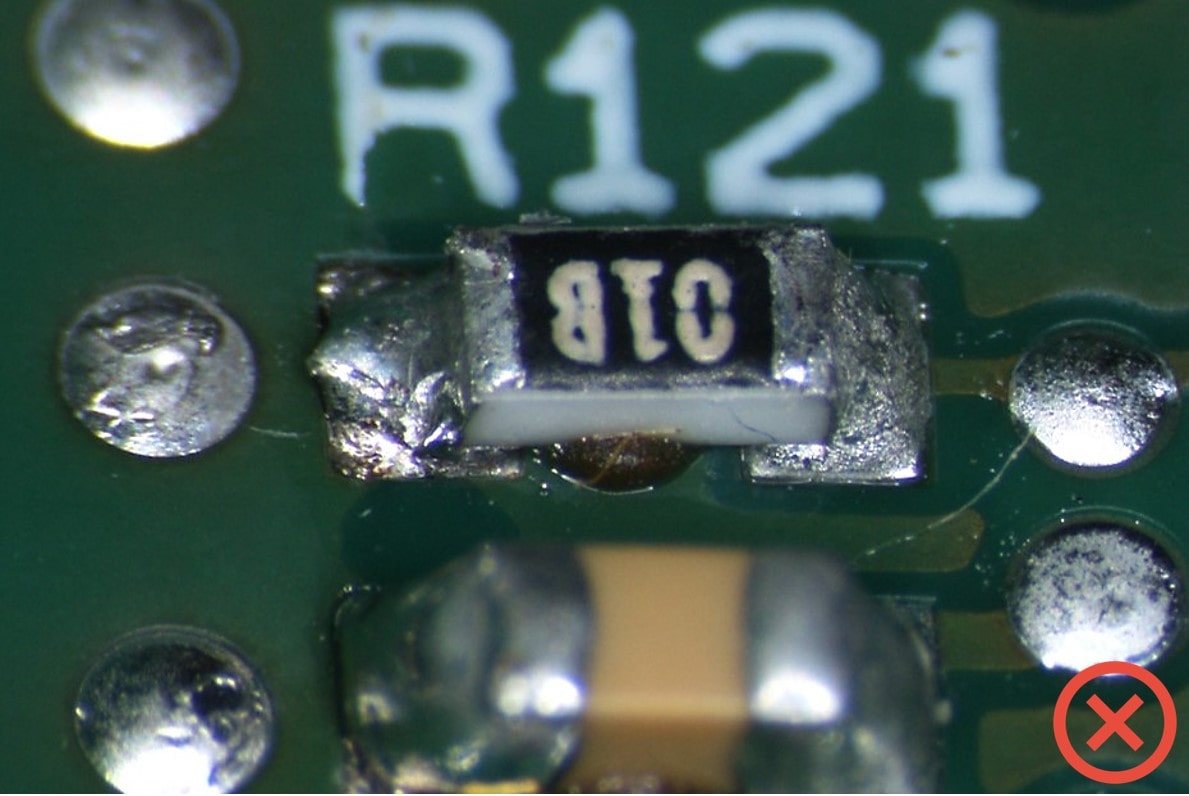

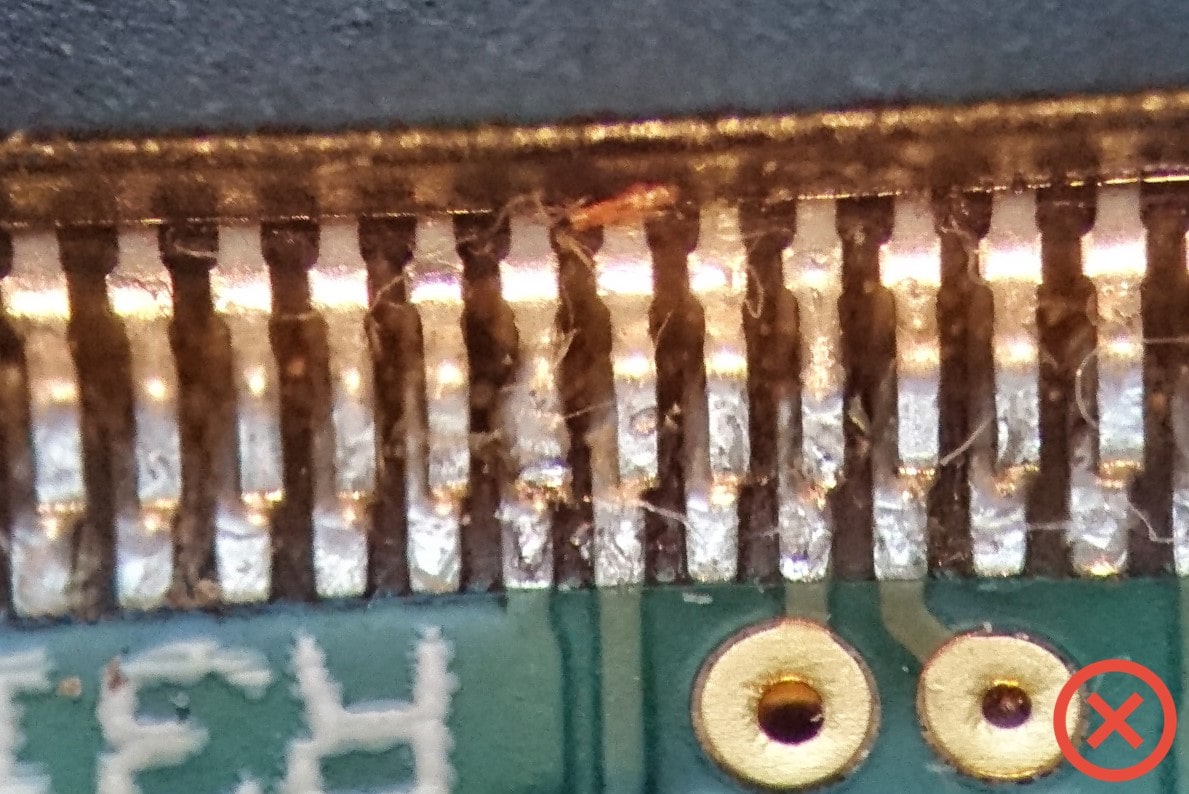

PCBA: ![]()

![]() compliance vs IPC/ECSS criteria

compliance vs IPC/ECSS criteria

Wetting issue

Crack in the solder joint

Misalignment and cleanliness issue

Residual flux

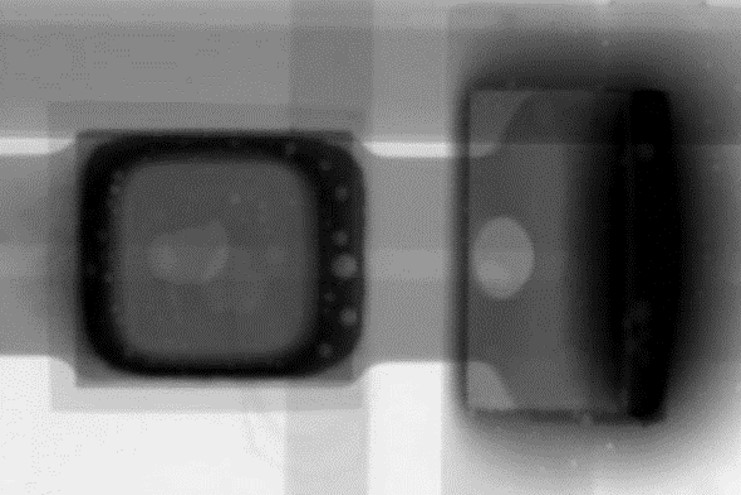

X-Ray Inspection

PCBA: IPC-A-610 / ECSS

2D void ratio (package w/ thermal dissipation pad)

2D void ratio (array package: BGA)

Filling of through hole vias

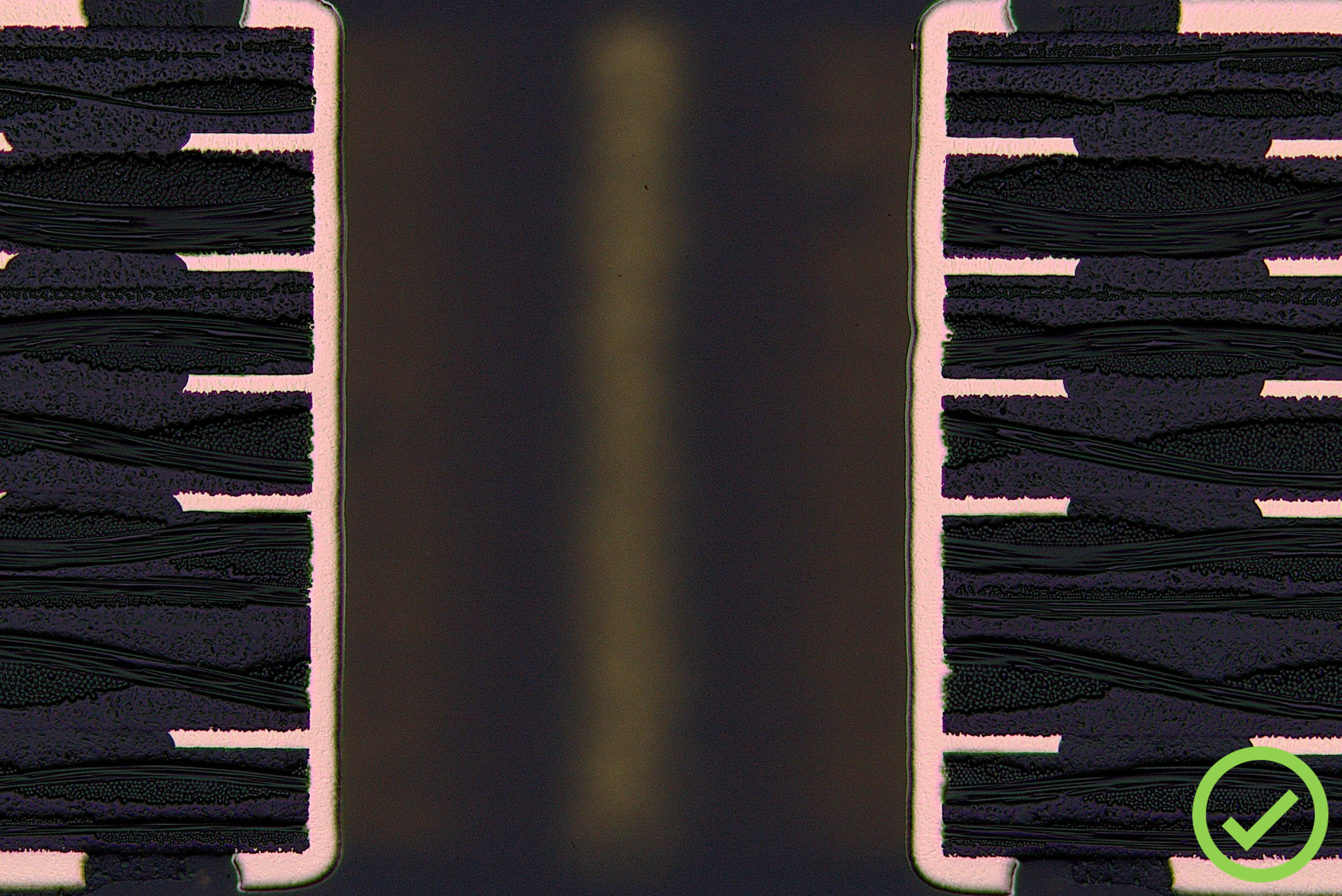

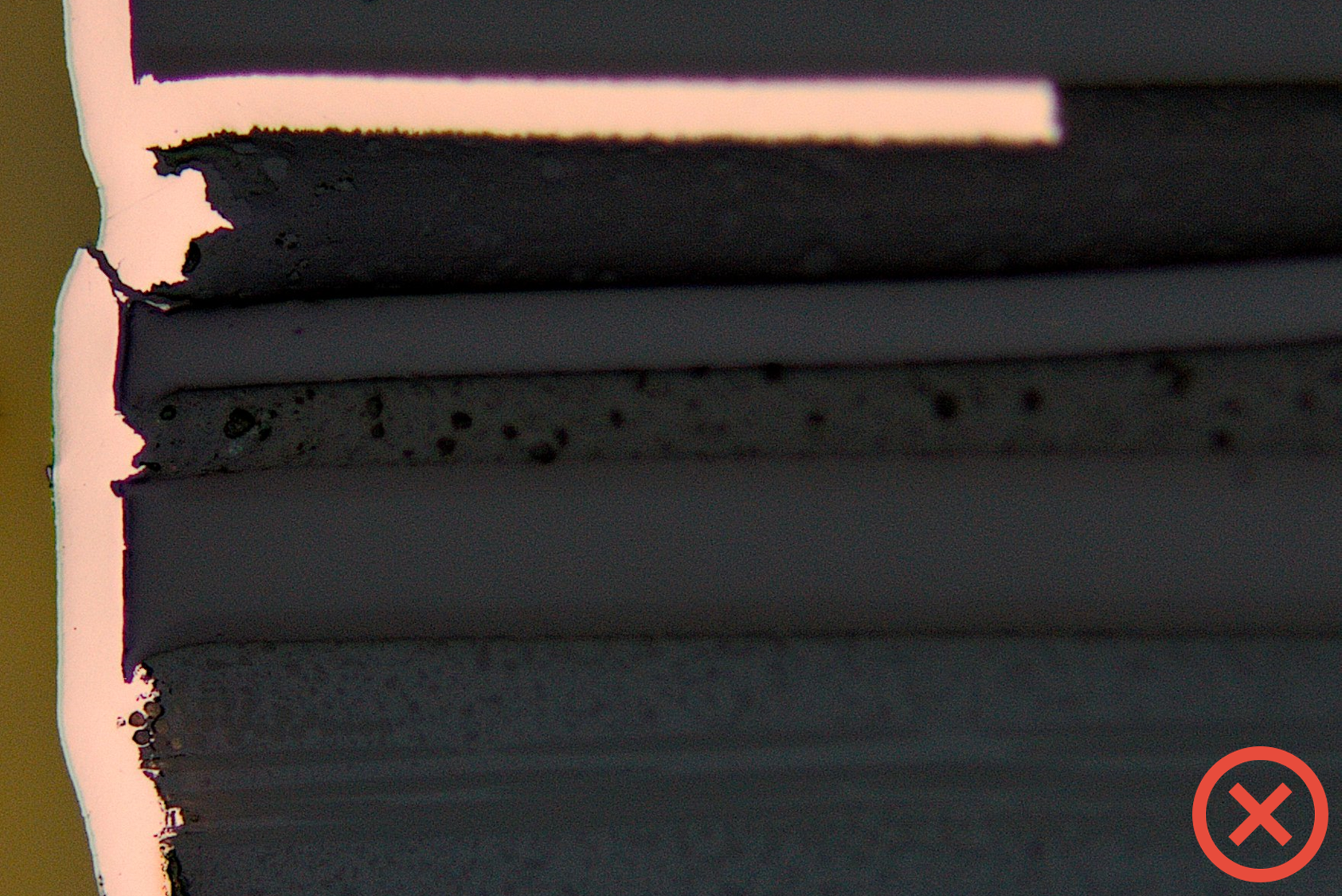

Optical inspection on microsection

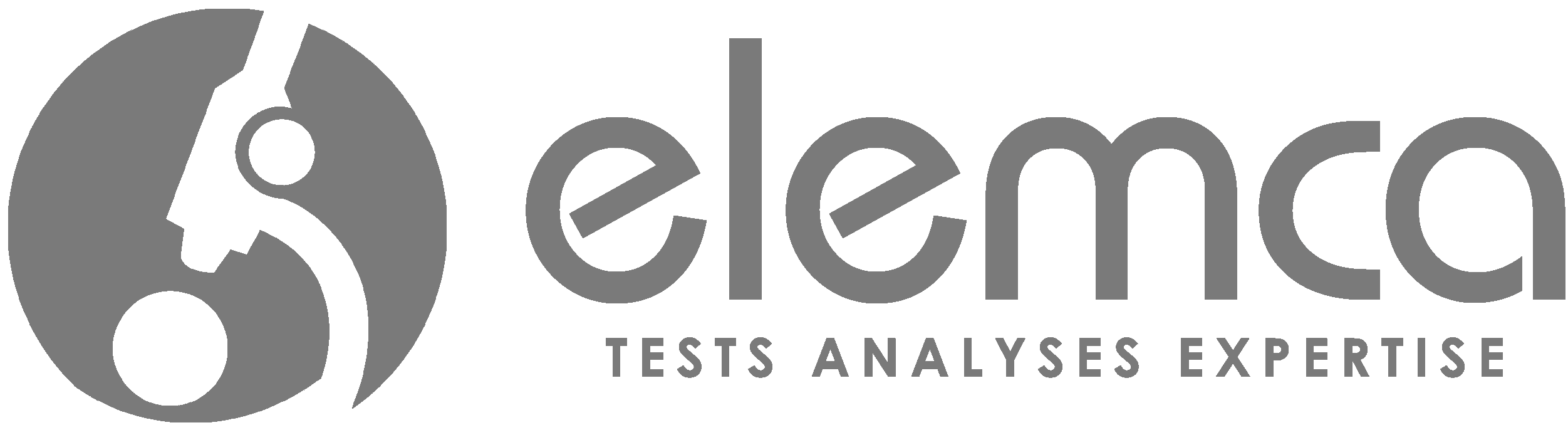

*Solder joint thickness, stand-off and homogeneity

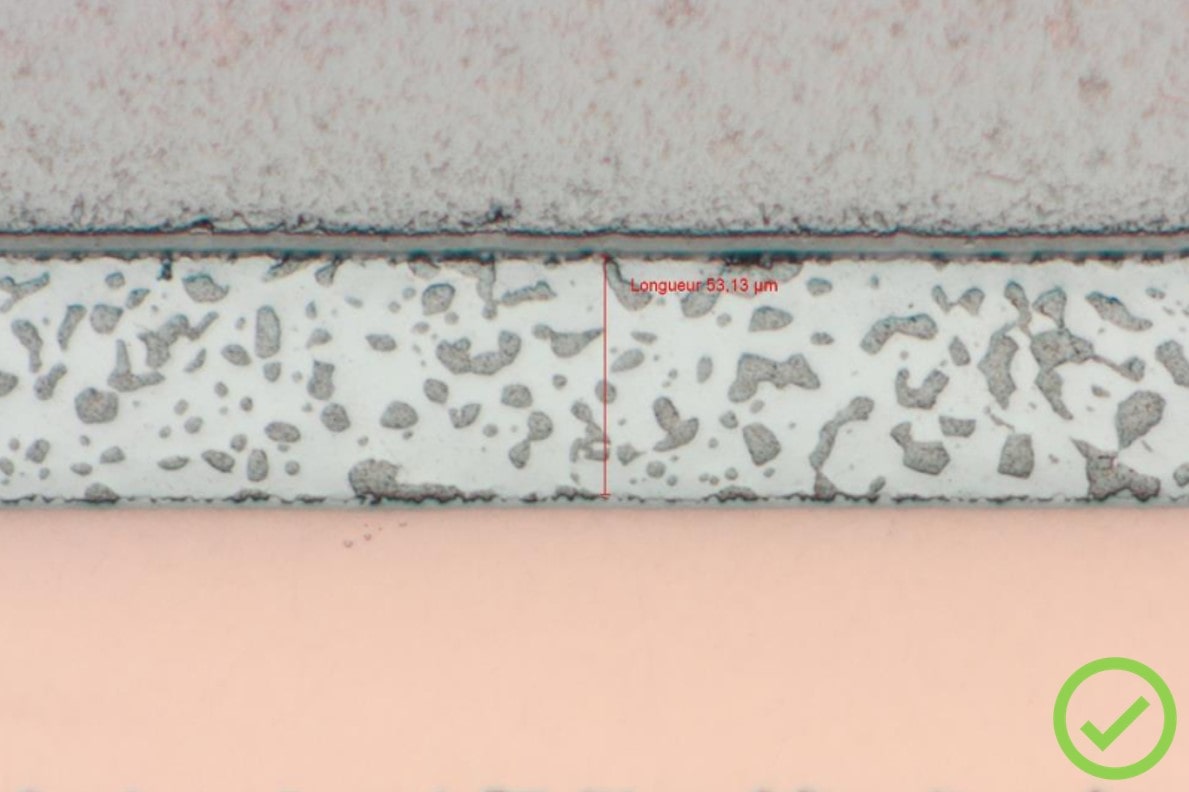

*Voids + bad alignement (endings / footprint)

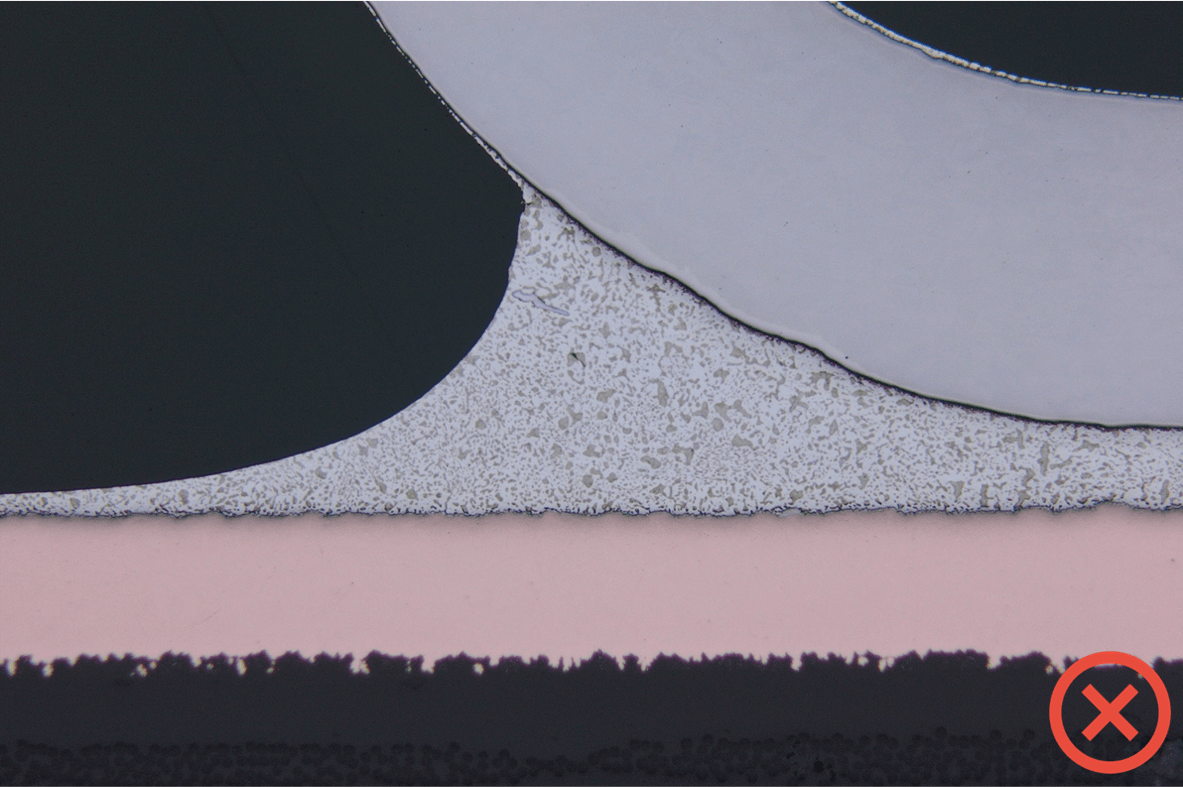

*Crack in the solder joint

**Copper thickness, PCB integrity (laminate pads, internal tracks)

PCB : ![]()

![]() compliance vs IPC-A-600*, IPC-6012** or IPC 4552*** (ENIG)

compliance vs IPC-A-600*, IPC-6012** or IPC 4552*** (ENIG)

No delamination or crack in the prepreg, fibers and metal tracks

*Crack in the via

**Excessive shrinkage of the resin

***Corrosion pitting + cracks in the nickel