Your job brings you face to face with major challenges:

💪 Validating the reliability of your equipment for applications in harsh environments

✅ Qualifying the launch of new products or new machines on your assembly lines

⚠ Verify the authenticity of component batches sourced from unofficial distributors

🚨 Obtain a clear diagnosis following the appearance of failures (field return, production issue...)

Our technicians and engineers provide you with all their responsiveness and expertise to deal with these problems.

Discover ELEMCA's services to meet your needs at every stage of your electronic development:

I WANT TO...

MAKE MY ELECTRONIC DESIGN CHOICES MORE RELIABLE

→ physical / numerical assessment of technologies & materials

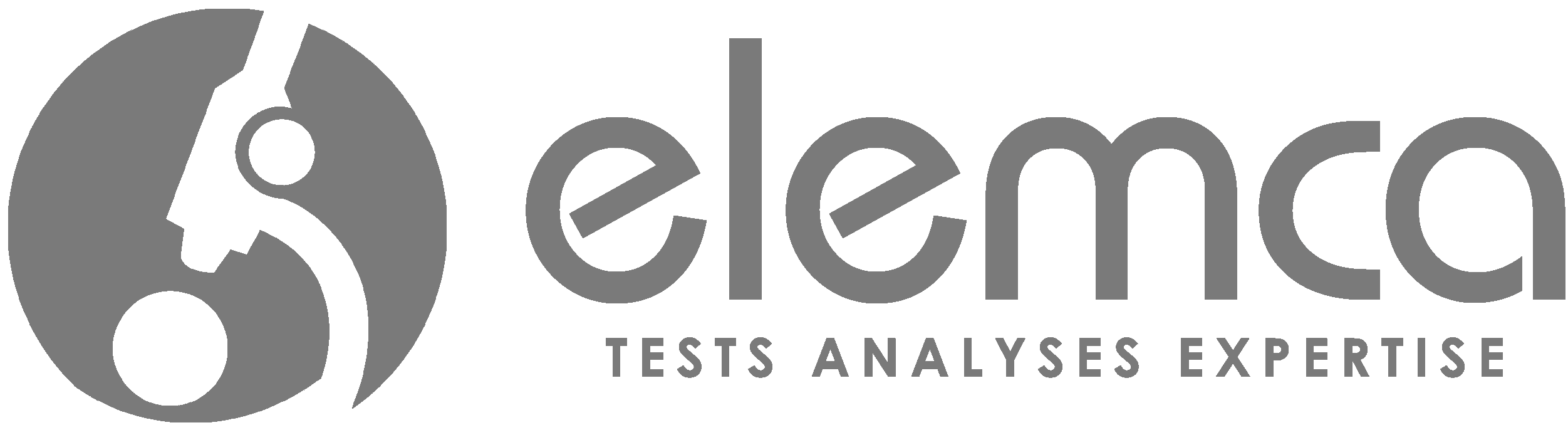

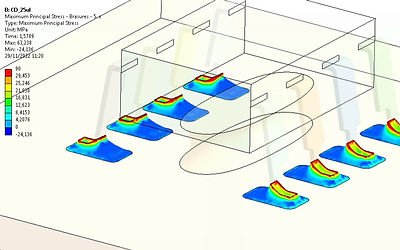

Simulate risk zones: heat dissipation or high mechanical stresses

Choose the right material based on its properties (expansion, hardness, outgassing...)

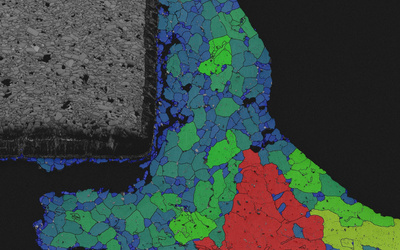

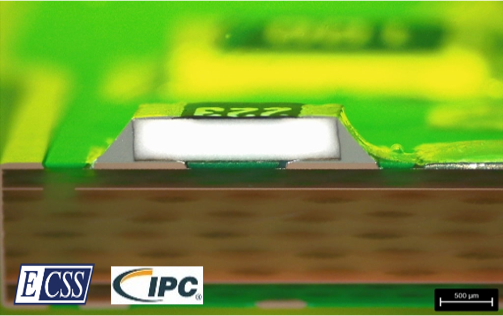

Identify the metallurgic ageing phenomena for solder joints (RoHS, SnPb)

Our studies are based on a mixed numerical and physical approach:

- Numerical simulation of thermal or mechanical behavior

- Physical characterization of solder joint metallurgy, extraction of material properties

You put your electronic design choices to the test, to either set them in stone or improve them.

CHECK THE CONFORMITY OF PRINTED CIRCUITS AND COMPONENTS

→ authenticity, manufacturing quality, qualification

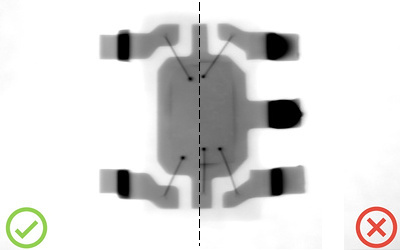

Validate the authenticity of components coming from an untrusted source

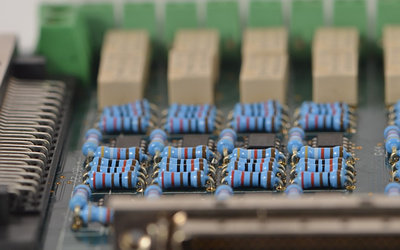

Qualify the manufacturing quality of assembled or bare printed circuit boards

Assess the reliability of my products towards harsh environnments

Our controls (visual inspections, X-rays, microsections: micrographic/metallographic sections) and tests (thermal cycling, moist heat, thermal vacuum) are carried out in accordance with a wide range of standards (ECSS, IEC, IPC, JEDEC, MIL-STD or Customer standards).

You can ensure the conformity of your electronic boards or the authenticity of your batches of high-risk components.

UNDERSTAND THE ROOT CAUSE OF FAILURES

→physics of failure, failure mechanism identification

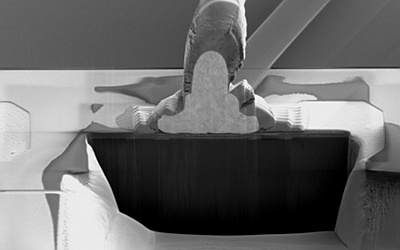

Identify the defect's electrical signature

Non-destructive failure localization

Access the defect and characterize it to explain the root cause

Our Materials & Electronics specialists identify and explain the probable root cause and associated failure mechanisms in a detailed expert report.

You know any of the weak points of your product (design, assembly, integration, use) so you can find an effective corrective solution.